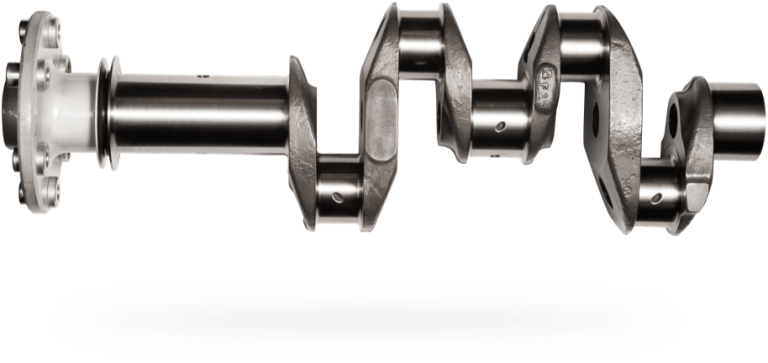

As a focus of innovation at the Lycoming Factory, we transformed how we manufacture crankshafts. Genuine Lycoming Crankshafts receive a hardening process,making the core of your engine even more reliable.

Watch Our Unique Ion Nitriding Process in Action

Introducing an ion nitriding treatment.

Not only does the ion nitriding system differentiate our crankshafts from the rest, but it also reduces our engine lead time by three days.